These were parts they’d discarded, but could have used. He got looking at parts that had failed the specified tolerances, but actually still fit.

Stan’s job was to find ways to produce them faster. As is often the case in wartime, they were not making them fast enough.

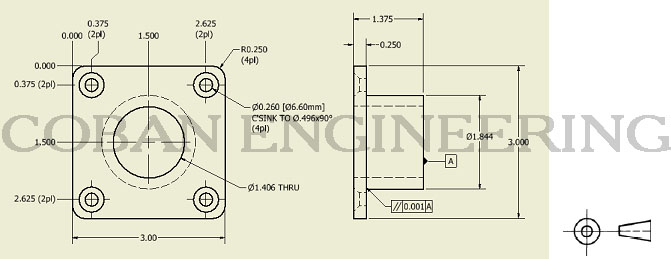

Once upon a time there was a fellow named Stan Parker who was working for England on Torpedoes. History and Background of Geometric Dimensioning and Tolerancing GD&T actually brings some order to that complexity and makes it systematic. When you consider all the different kinds of geometry found in machined parts, it’s no wonder that cataloging all the defects in that geometry gets a bit complicated. A shaft could be slightly bent, slightly tapered, slightly tilted, and slightly offset from where it was intended. If GD&T seems complex, it is only because there is a long list of ways a physical part can deviate from the geometric ideal of what the designer had in mind. If you’re a CNC’er, you’re already quite familiar with them.Ī simple drawing with GD&T symbols. As you recall, Cartesian coordinates are just X, Y, and Z measurements from an origin. Each work piece is described in terms of “zones of tolerance” that are relative to the Cartesian coordinate system. It is very precise as well as concise relative to these older systems. GD&T is a significant improvement over traditional older systems for describing dimensions that relate to the fit, form, and function of parts. It is a mathematical language, though it does not require you to be a math expert in order to understand and use the system. GD&T is a standardized international system based on symbols that can be clearly understood by anyone that is familiar with the standard.

This course will teach you the basics of how to understand GD&T symbols and their use. GD&T is a particular set of conventions used on engineering drawings (often called “prints” from the older “blueprints”) that communicate how parts should fit together and how they function. These specifications are shown on engineering drawings, which are normally produced by CAD software. Parts that are manufactured in a shop must meet specific specifications. GD&T, the abbreviation for Geometric Dimensioning and Tolerancing, is a set of standardized symbols and conventions that are used to describe parts in a way that makes it easier for customers, manufacturers, and other supply chain participants to successfully communicate.

0 kommentar(er)

0 kommentar(er)